Cone crushers are essential machines in the mining and aggregate industries, widely used to crush various types of rock into smaller, more manageable sizes. Understanding how they operate can seem complex at first, but when broken down into simple illustrated steps, the process becomes easy to grasp. A cone crusher works on the principle of compressive force. It consists of a rotating mantle inside a concave bowl. The raw material is fed into the top of the machine and gets crushed as it moves downward through the narrowing space between the mantle and the bowl liner. The continuous motion and pressure exerted by the mantle help break the material into finer particles. The operation begins when the feed material is dropped into the feed opening at the top. This material then descends by gravity into the crushing chamber. The cone-shaped mantle, mounted on a spindle, rotates eccentrically. This rotation doesn’t occur in a perfect circle but in an elliptical motion, causing the mantle to squeeze the rock against the stationary concave surface. The eccentric motion is powered by a motor connected to a drive shaft, which turns the mantle in a precise, controlled manner.

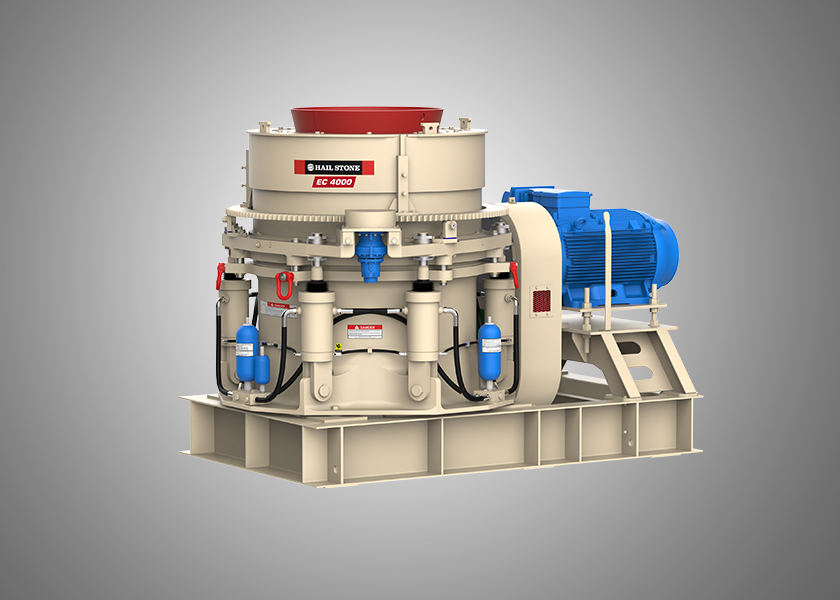

As the space between the mantle and concave decreases, the rock gets compressed and fractured into smaller chunks. One of the key illustrated steps in a cone crusher diagram operation is the crushing stroke the period during which the mantle moves toward the concave, applying maximum force. This is followed by the release stroke, where the mantle moves away slightly, allowing broken material to fall further down for more crushing. This repetitive cycle continues until the particles reach the desired size and exit the crusher through the bottom discharge opening. The size of the output can be adjusted by raising or lowering the mantle, effectively changing the gap between the mantle and concave. Lubrication systems play a vital role in cone crusher operation. These systems ensure that moving parts are well-lubricated, reducing friction and preventing overheating. Additionally, hydraulic systems are used to adjust the setting, clear blockages, and even provide overload protection.

If an crushable object enters the chamber, the hydraulic system allows the mantle to lift temporarily, preventing damage to the machine. Illustrated guides often show cutaway diagrams that highlight key components such as the feed hopper, main shaft, drive assembly, crushing chamber, and discharge area. These visual aids help learners easily identify the path of the material and the working motion of the internal parts. JXSC provides well-illustrated manuals and diagrams that make it easier for operators to grasp cone crusher functionality and ensure safe, efficient operation. By following these illustrated steps, users can not only understand the mechanism but also operate the cone crusher efficiently and safely. In conclusion, cone crushers may seem intricate, but with the help of clear diagrams and a step-by-step breakdown, their operation becomes straightforward. From material feeding to final discharge, each movement is designed for optimal crushing efficiency.