Piping and Instrumentation Diagrams P&IDs are critical documents used in the design and operation of industrial processes, helping engineers, operators, and technicians understand the relationships between different components in a system. Drawing and interpreting P&ID symbols requires a set of specialized tools, both software and manual, that enable users to create, modify, and accurately read these complex diagrams. Below, we discuss some of the essential tools for working with P&ID symbols. In modern engineering practice, most P&IDs are created using Computer-Aided Design CAD software. CAD tools allow engineers to draw, modify, and visualize P&ID diagrams with precision. Popular CAD software like AutoCAD, SolidWorks, and Plant 3D offer features specifically tailored for piping design. These programs include extensive libraries of standard P&ID symbols, making it easier to create diagrams that adhere to industry standards. These tools also enable the easy manipulation of objects, such as valves, pumps, and instrumentation, to represent the physical layout and functional flow of systems.

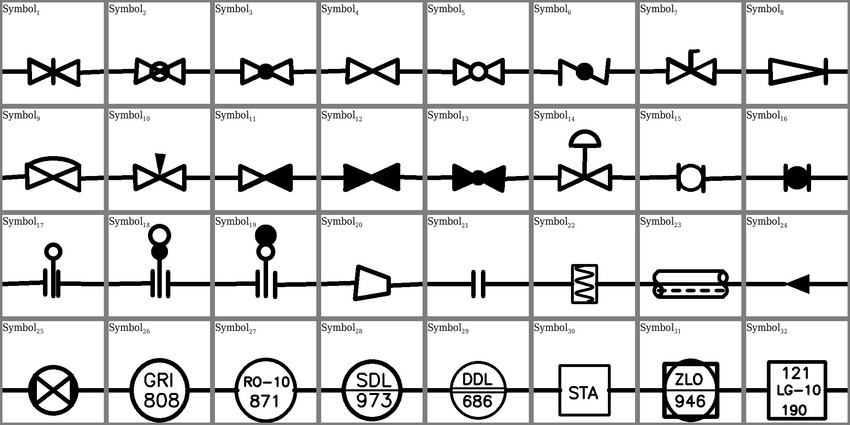

AutoCAD, for example, offers P&ID-specific templates and a symbol library that engineers can use to quickly insert symbols for piping, instrumentation, and equipment. This tool also supports automatic updates, ensuring that as the design evolves, the corresponding P&ID is automatically updated with the new modifications. The precision offered by CAD software is invaluable when creating complex diagrams that need to be clear and accurate. P&ID symbols must adhere to industry standards to ensure consistency and ease of understanding. The most common standards are those set by organizations like the International Society of Automation ISA, the American National Standards Institute ANSI, and the International Organization for Standardization ISO. To streamline the creation process, most CAD tools include symbol libraries that contain standard P&ID symbols for various components, including pipes, valves, instruments, and equipment. These libraries are essential for consistency across designs and ensure that anyone who reads the diagram, whether they are engineers, maintenance personnel, or operators, can interpret it correctly.

While custom symbols can be created for unique equipment, using standard symbols from these libraries helps avoid confusion and mistakes. It provides a guide to the symbols used in the diagram, detailing what each symbol represents. A well-organized legend will typically include the symbol for each component, along with its name, function, and specifications, ensuring that anyone reading the diagram can quickly understand the representation. For example, the symbol for a valve may be accompanied by a note indicating the type of valve and its function within the system. Legends are particularly helpful when working with complex systems, where multiple symbols might represent similar components but with slight differences, such as flow directions or valve types. The key allows for quick interpretation of these subtle variations and avoids misinterpretation, which could lead to safety hazards or system inefficiencies. While p&id symbols provide a detailed, component-level view of a system, Process Flow Diagrams PFDs give a broader overview of the process, focusing on the major equipment and flow paths.